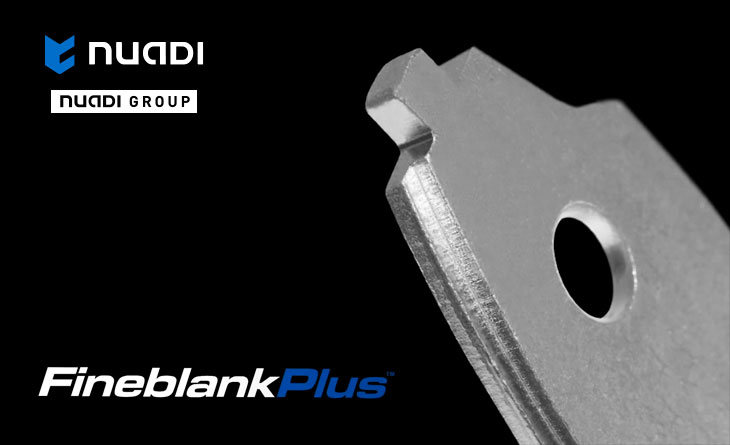

FineBlank Plus

NVH is critically impacted by brake pad flatness. NUADI FineBlank Plus maintains flatness throughout the entire pad manufacturing process like no other technology.

The Internal Combustion Engine (ICE) has been powering billions of vehicles during the last 100+ years and OEMs globally tightened caliper performance standards to achieve near zero drag for fuel consumption and emission regulations and improved NVH. Electric Vehicles (EV) are disrupting the automotive industry and their NVH/comfort requirements are stricter, safety regulations demand additional braking capability and pads life is much longer.

To meet these NVH stringent requirements, system designers need to focus deeply on aspects of backing plate quality beyond pure basic dimensions:

• Backing plate stability under temperature environment

• Backing plate stability under mechanical treatments

• Flatness change over the entire pad assembly manufacturing process

We must bridge these characteristics to caliper performance and their impact to NVH.

NUADI FineblankPlus is a backing plate stamping technology that:

• Provides a piece-to-piece consistent flatness through the entire brake pad manufacturing process.

• Improves material usage.

• Reduces the cost of tooling for a manufacturing process even more robust that fine blanking.

• Meets or exceeds OE specifications.

NUADI Group provides a fully integrated solution for the EV Original Equipment brakes.

(NUADI and SADECA are brands of the NUADI Group)